Rubber has become an essential material in the mining industry, playing a critical role in various applications, from conveyor belts to rubber lining for mineral processing. The history of rubber in mining dates back to the early 19th century, and its development has revolutionized the industry. We explore the evolution of rubber in mining, highlighting its key milestones and innovations.

The Early Uses of Rubber in Mining (1800s-1920s)

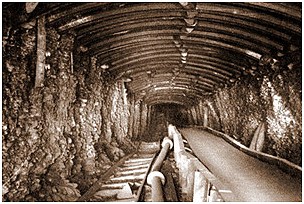

In the early days of mining, rubber was primarily used for personal protective equipment such as boots, gloves, and hoses. Miners valued rubber for its durability, water resistance, and flexibility. As the industry grew, so did the demand for rubber products. In the late 19th century, the first rubber conveyor belts were introduced, marking the beginning of a new era in mining technology.

Conveyor Belting (1920s-1950s)

The 1920s saw significant improvements in conveyor belt technology, with the introduction of cotton and rubber blends. These new belts were stronger, more durable, and resistant to wear and tear. As mining operations expanded, conveyor belts became a crucial component, enabling efficient transportation of materials over long distances. By the 1950s, rubber conveyor belts had become the industry standard, with mines worldwide relying on them for their operations.

Rubber Lining for Mineral Processing (1950s-1980s)

In the mid-20th century, rubber lining technology emerged, revolutionizing mineral processing. Rubber lining provided superior resistance to corrosion and abrasion, making it an ideal material for tanks, pipes, and other equipment. This innovation enabled mines to process materials more efficiently and effectively, leading to increased productivity and reduced maintenance costs.

Modern Uses of Rubber in Mining (1980s-Present)

Today, rubber plays a vital role in various mining applications, including:

- Advanced conveyor belt designs with improved durability and resistance

- Specialized rubber products for specific mining applications, such as wear-resistant linings and seals

- Continued innovation in mineral processing, including the development of new rubber compounds and technologies

Rubber has come a long way in the mining industry, from its early uses in personal protective equipment to its current applications in conveyor belting and rubber lining. Its durability, flexibility, and resistance to wear and tear have made it an indispensable material in modern mining. As the industry continues to evolve, it's likely that rubber will remain a critical component, driving innovation and progress in mining technology.